What is our ECU refurbish service?

We proudly offer the most comprehensive refurbish service for OBD1 (1992-1995) Honda/Acura ECUs

Place an order for our refurbish service here

Why does my ECU need to be refurbished?

The 1992-1995 Honda/Acura OBD1 (commonly refered to as "P28") are notorious for their defective leaking capacitors which is the main cause for their inevitable failure. Over the last 30 years these capacitors have been leaking corrosive acid onto the circuit board which eats through the protective conformal coating, the solder mask layer, then finally the small traces that connect everything together. In the past it has been common practice to throw these damaged/faulty ECUs away and replace them with another unit from a junkyard, unfortunately this has lead to a shortage and major price increase for these dwindling units. Luckily for the Honda/Acura community we have come along to lovingly restore the remaining computers to ensure they remain powering your projects forever, we even cover everything we replace for life!

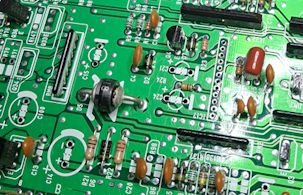

example of a leaking capacitor

Why should I choose OxyTuned?

While there are many other companies and inviduals who are offering cheaper "refurbish" services most of these are far inferior to our service. We don't just remove and replace the failed capacitors like most others are known to do, we restore the entire circuit board. We have continued to receive countless ECUs that have already been serviced by others and been treated with an inferior refurbish service, due to this we offer a lifetime warranty on every part we replace or repair we make to ensure that the customer never needs to send it in for the same repair again.

What does the refurbish process consist of?

We will first perform a courtesy inspection & diagnostic on the ECU to identify any problems or damage, the diagnosis will be documented and provided to the customer. If any additional repairs or modifications are required or recommended we will acquire approval before starting any work.

We start by removing all electrolytic capacitors and other parts set for replacement. After parts have been removed the board is thouroughly cleaned and stripped on both sides of it's factory conformal coating and any compromised solder mask. The board will then be treated to stop the spread of any corrosion left by acid from the capacitors and traces in the affected areas will be checked for damage and continuity.

example of a stripped circuit board

After the board has been stripped and cleaned we will re-apply solder mask to any exposed areas and make any necessary additional trace repairs. Once repairs have been verified we will install new high quality Würth capacitors and any other required replacement parts. Finally the circuit board will be given a fresh coat of UV reactive conformal coating on both sides before being re-assembled and tested for full functionality.

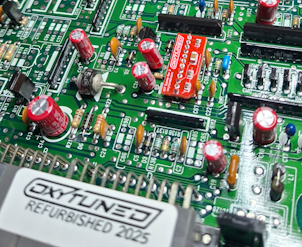

example of a completed refurbish